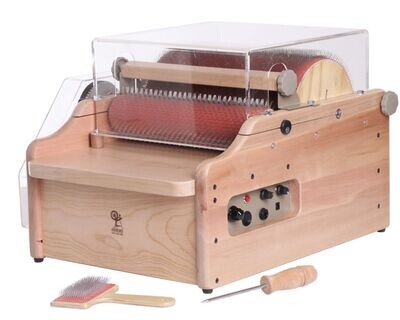

Louet XL Drum Carder

The Louët XL carder is a workhorse. With a width of 12 inches, batts of up to approx. 120 grams can be carded. Mixing colors and fibers is also easy on these carders.

The XL carder is available in 46 tpi (teeth per square inch) and 72 tpi. If you are primarily carding coarser wool or greasy fleece, the 46 tpi is your best option. If you will primarily card finer fibres, the carder with 72 tpi is most suitable. The carding cloth is made of nickel-plated steel wire on a bed of cotton and natural rubber, which gives it a long life.

The frame of the carder is made of water resistant birch plywood with a white HPL top layer. The drums are driven by a closed gear system. As a result, the carder requires very little maintenance and this keeps fiber from getting caught up in the gears.

In carders, as a rule, the acceleration between the drums is stated. For the standard carder it is 4:1. However, more important for the effectiveness of the carder is the difference in surface speed between the large and the small drum. To calculate this, multiply the acceleration by the ratio of the diameters of the two drums. For the standard Carder, this speed ratio is 9:1.

SPECIFICATIONS

- Teeth are spaced at 72 teeth per square inch or 46 teeth per square inch

- Doffer Brush

- Doffer Pin

- 2 Table Clamps

- Drum Width: 11.75" (30cm)

- Surface Speed Ratio: 12:1

- Complete Instruction Manual by Deb Menz

- Fully Assembled

An instruction manual written by well known author and fiber artist Deb Menz is included with all drum carders. The Louet Drum carders are made of laminated birch and have a hard white coating. In order to ensure a long life, the teeth on all Louet carders are made of high grade plated steel wire. All gearboxes are enclosed to prevent fibers entering the gear system. For drum carders it is common to mention the gear ratio that drives the licker-in when you rotate the large drum. However, what really counts for carding is the ratio of the surface speed of both drums, because the difference of surface speed does the carding. You get this surface speed ratio by multiplying the gear ratio with the ratio of the diameters of the large drum and the licker-in.

Meet the Louet XL Drum Carder

How to Clean Your Louet Drum Carder